Packaging Details: Standard sea packing or as customer's request

Delivery Time: 3-15 working days according to the number of orders placed by customers

Payment Terms:L/C, D/A, D/P, T/T, Western Union, MoneyGram

Supply Ability: Supply 100,000 pieces per month

Model Number:OEM customization

If you have any questions, please feel free to contact us.

Jiangsu Hailiang Dongfang Import and Export Co., Ltd.

—— PRODUCT INTRODUCTION

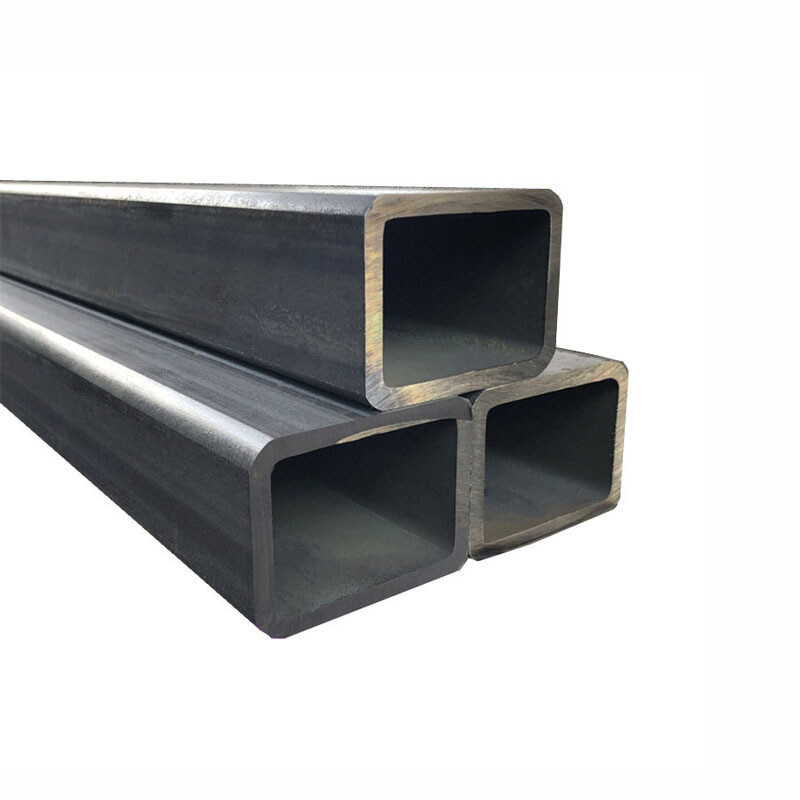

Carbon Seamless Steel Pipe/Tube Metal Material Apl5l A36 A53 Cold/Hot Rolled Carbon Weld

There are two kinds of pipes, seamless pipes and welded pipes, with different uses.

Seamless tubes are generally thinner and lighter, and are therefore most widely used in bicycle production and fluid transfer. The seamed tube is heavier and stiffer for better consistency and durability. Pipes used for gas transport, electrical conduits and plumbing are often slotted. During production, several parameters should be controlled to maintain the properties required for the application. For example, the design of the pipe diameter is directly related to how it is used. While smaller diameter tubing can be used for injection needles, larger diameter tubing can be used for transportation in cities. Wall thickness is also an important control parameter as it directly affects the strength and flexibility of the pipe

How are pipes used?

Pipes are used for construction, transportation and manufacturing. Different materials, design features and production methods of steel pipes are constantly evolving and vary according to the application

Structural use

Structural uses are usually building and construction, where the building material is often referred to as steel pipe. Steel pipes are used to provide extra strength and stability to particularly tall buildings or structures. Two types of steel pipes are used structurally as end bearing piles and friction piles, both of which are designed to transfer loads from buildings. In these applications, the steel pipes are driven deep into the ground before the foundation is laid, which constitutes a great support for the building, especially if the ground is not firm. Another structural application of steel pipes is scaffolding poles, which allow construction workers to access all inaccessible areas of a building. They are made by interconnecting steel pipes to act as cages around the building

Manufacturing use

In manufacturing applications, steel pipes are used for many different purposes. Guardrails are one of the most common uses for providing a safety feature for stairs and balconies or on the street for cyclists and pedestrians. Steel pipes can also be used as safety bollards to block off vehicular traffic areas to protect people, buildings or infrastructure. In addition, steel pipes constitute the choice of outdoor venue furnishing. Many commercial bike racks are formed by bending steel pipes. The high toughness and strength of steel make it safe against theft

traffic use

The most common use of steel pipe is the transportation of products, as the properties of the raw material are ideal for long-term installation. As mentioned earlier, different applications require different properties, because for low pressure applications, the steel pipe will not exhibit ultra-high strength as it will not be subjected to large loads. More specialized applications used in the oil and gas industry may require stricter specifications due to the hazardous nature of the product and the potential for increased stress. These requirements bring higher costs and quality control becomes more critical

product description

Jiangsu Hailiang Dongfang Import and Export Co., Ltd.

—— ABOUT US

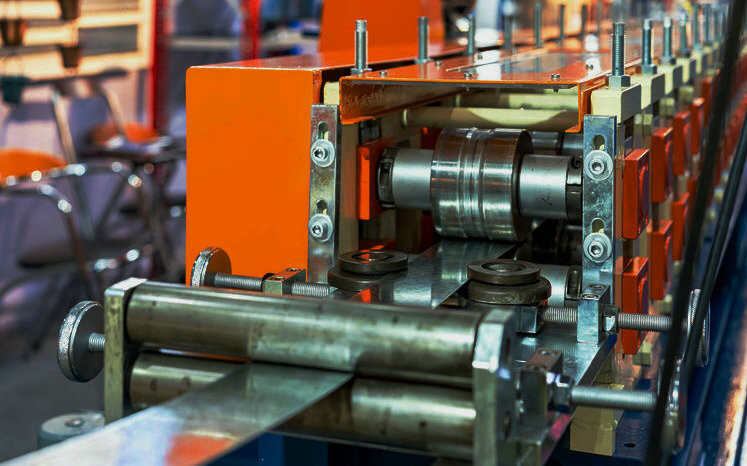

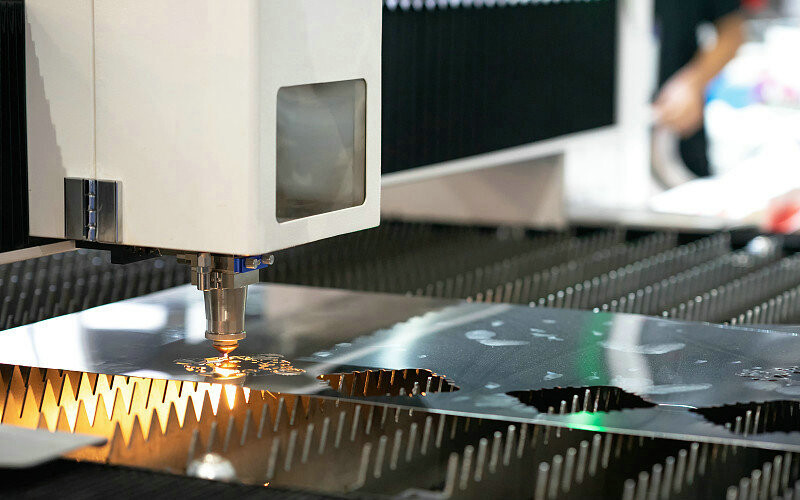

Jiangsu Hailiang Dongfang Import and Export Co., Ltd. is a professional metal parts manufacturer with years of experience in the industry, specializing in the production of various precision metal parts. Our business covers a wide range of areas, including CNC machining, metal stamping, mold parts manufacturing, forging, and casting, to meet the diverse needs of our customers. As a quality focused enterprise, we are committed to providing high-quality products at highly competitive prices. Every process is strictly controlled, and all products are screened layer by layer by advanced testing equipment and professional inspection teams to ensure their excellent performance, safety, and reliability. In addition, we attach great importance to after-sales service and have a professional and efficient customer service team to provide technical support and solutions to customers at any time, ensuring that customers have no worries during use. Jiangsu Hailiang Dongfang Import and Export Co., Ltd. has won the trust and praise of its customers with exquisite craftsmanship, strict quality management, and attentive service.

Jiangsu Hailiang Dongfang Import and Export Co., Ltd.

—— WHY CHOOSE US

High quality raw materials

Selecting high-quality steel raw materials ensures excellent product quality and performance from the source, leaving your project worry free.

Strict quality control

With advanced testing equipment and a professional team, all products undergo multi-stage rigorous testing to meet international standards, ensuring reliable and guaranteed quality.

Efficient logistics service

Cooperate with well-known logistics companies to establish a global logistics network, ensure fast and accurate delivery of goods, and ensure that your project progress is not affected.

after-sales team

An experienced after-sales team is always on standby to solve any problems you may encounter during use, providing technical support and attentive service.

Competitive Price

Factory direct sales, providing customers with more cost-effective products.

Jiangsu Hailiang Dongfang Import and Export Co., Ltd.

—— LEAVE A MESSAGE

Jiangsu Hailiang Dongfang Import and Export Co., Ltd.

—— RECOMMENDED PRODUCTS

ASK FOR A QUOTE