Packaging Details: Standard sea packing or as customer's request

Delivery Time: 3-15 working days according to the number of orders placed by customers

Payment Terms:L/C, D/A, D/P, T/T, Western Union, MoneyGram

Supply Ability: Supply 100,000 pieces per month

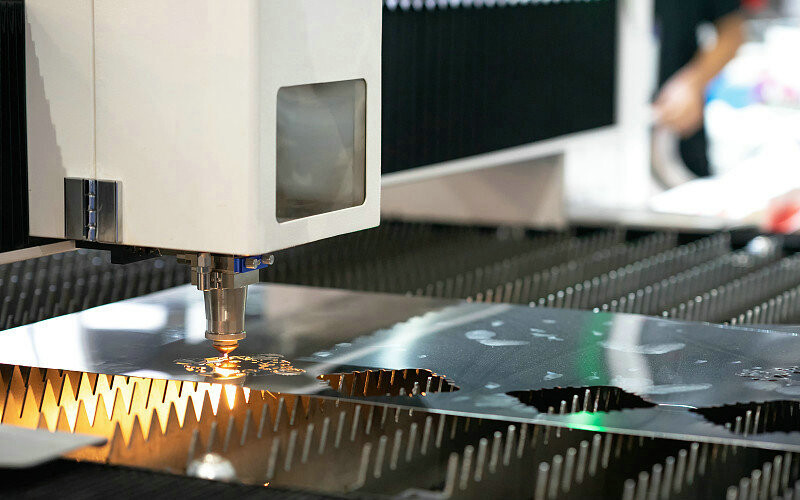

Model Number:OEM customization

If you have any questions, please feel free to contact us.

Jiangsu Hailiang Dongfang Import and Export Co., Ltd.

—— PRODUCT INTRODUCTION

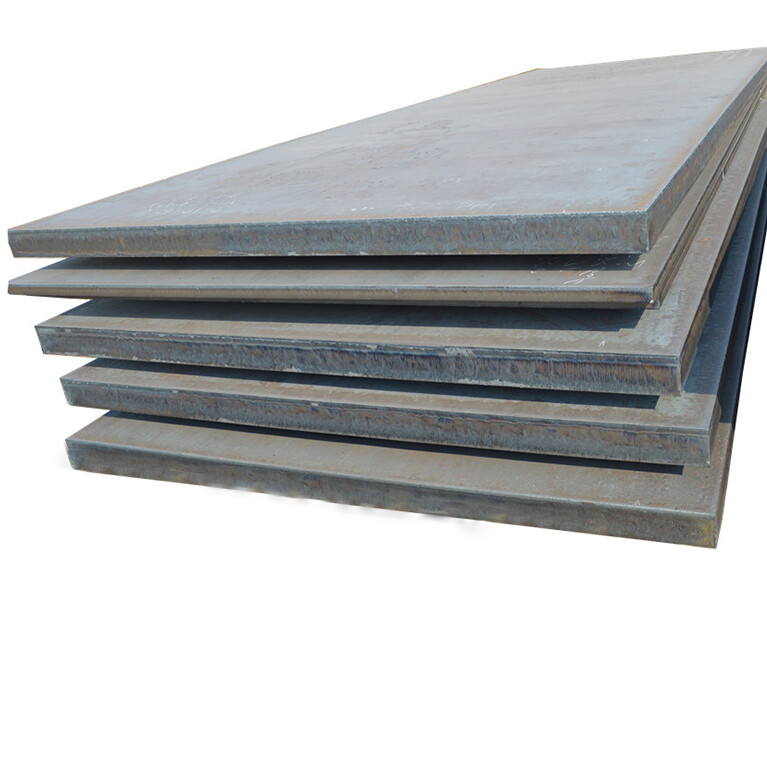

Low Carbon Steel Sheet Iron Cold Rolled Steel Sheet Price Corrugated Sheet Metal Cold Rolled Carbon Steel Sheet

Carbon Steel Plate - Things You Should Know

Carbon steel sheets are generally considered to be steels that do not contain too many alloying steel elements. Usually the elements are C, Mn, P, S, Si, other than that, there is no minimum limit for elements such as Al, Cr, Ni, Mo, V, etc.

Carbon steel sheets are available in different grades based on carbon content and strength

There are low carbon, medium carbon and high carbon steel plates. The higher the carbon content, the more durable and stronger the sheet will be. There are further sub-categories based on thickness and use as well as the forming process. Typically carbon steel sheets are available in thicknesses ranging from 0.4mm to 80mm, widths from 1000mm to 45000mm and lengths up to 18m. But the length is customizable, which helps customers fit them into various applications. One can also use them to make cold rolled coils

Carbon content level of each carbon steel plate

Low carbon steel plate: the carbon content is between 0.06% and 0.25%, we also call it low carbon steel plate

Medium carbon steel plate: C content 0.25% to 0.55%

High carbon steel plate: 0.55% to 1.0%, also called hard steel plate

As the carbon content increases, the hardness of the steel plate increases

What are the different types of carbon steel plates available?

Carbon steel sheets are widely used in different industries. Classified according to carbon content from low to high. It is also classified according to their use and application. Machinery and production companies use different types of carbon steel plates as the base material for component construction. Its durable properties make it ideal for a variety of manufactured parts. In addition to carbon steel plates, there are also marine steel plates, shipbuilding or construction steel plates, structural steel plates, pipeline steel plates and stainless steel plates

Below are the different types of carbon steel plates and their uses

Carbon structural steel plate

It is mainly used in the construction industry, therefore, quality, durability and performance must meet the highest standards. They must withstand extreme loads and pressures and must be corrosion resistant. it is known by the name of architectural steel plate

boiler steel plate

These are high pressure panels commonly used to design vessels, boilers and thermal vessels. Carbon boiler steel plate has low corrosion properties and can withstand low heat. Several layers of chromium or nickel are added to make it suitable for use in a variety of environments

Carbon shipbuilding steel plate

Shipbuilding Steel Plates - These steel plates are in high demand, especially in the oil and gas industry, as they require very good quality thick plates. Most of these are manufactured to customer specifications and the steel used is certified as small laminar tears can be fatal

What standard does carbon steel plate refer to?

Carbon steel plate covers almost all common standards of steel plate/sheet

ASTM A36 Plate - Most Common Standard for Carbon Steel Plates

ASTM A283 Grades A, B, C - also the most common material in carbon construction

ASTM A516 – Steel Plates for Boilers and Vessels

ASTM A537 – Heat Treated Carbon Steel Plates for Fusion Welded Pressure Vessel and Structural Steel Plates

ASTM A573 - A carbon-manganese-silicon structural steel plate

ASTM A572 - The mechanical strength of ASTM A572 sheet is higher than that of A36. where light weight

ASTM A737 – Low Alloy Steel Plates for Boilers and Pressure Vessels

and many more

product description

Jiangsu Hailiang Dongfang Import and Export Co., Ltd.

—— ABOUT US

Jiangsu Hailiang Dongfang Import and Export Co., Ltd. is a professional metal parts manufacturer with years of experience in the industry, specializing in the production of various precision metal parts. Our business covers a wide range of areas, including CNC machining, metal stamping, mold parts manufacturing, forging, and casting, to meet the diverse needs of our customers. As a quality focused enterprise, we are committed to providing high-quality products at highly competitive prices. Every process is strictly controlled, and all products are screened layer by layer by advanced testing equipment and professional inspection teams to ensure their excellent performance, safety, and reliability. In addition, we attach great importance to after-sales service and have a professional and efficient customer service team to provide technical support and solutions to customers at any time, ensuring that customers have no worries during use. Jiangsu Hailiang Dongfang Import and Export Co., Ltd. has won the trust and praise of its customers with exquisite craftsmanship, strict quality management, and attentive service.

Jiangsu Hailiang Dongfang Import and Export Co., Ltd.

—— WHY CHOOSE US

High quality raw materials

Selecting high-quality steel raw materials ensures excellent product quality and performance from the source, leaving your project worry free.

Strict quality control

With advanced testing equipment and a professional team, all products undergo multi-stage rigorous testing to meet international standards, ensuring reliable and guaranteed quality.

Efficient logistics service

Cooperate with well-known logistics companies to establish a global logistics network, ensure fast and accurate delivery of goods, and ensure that your project progress is not affected.

after-sales team

An experienced after-sales team is always on standby to solve any problems you may encounter during use, providing technical support and attentive service.

Competitive Price

Factory direct sales, providing customers with more cost-effective products.

Jiangsu Hailiang Dongfang Import and Export Co., Ltd.

—— LEAVE A MESSAGE

Jiangsu Hailiang Dongfang Import and Export Co., Ltd.

—— RECOMMENDED PRODUCTS

ASK FOR A QUOTE