Packaging Details: Standard sea packing or as customer's request

Delivery Time: 3-15 working days according to the number of orders placed by customers

Payment Terms:L/C, D/A, D/P, T/T, Western Union, MoneyGram

Supply Ability: Supply 100,000 pieces per month

Model Number:OEM customization

If you have any questions, please feel free to contact us.

Jiangsu Hailiang Dongfang Import and Export Co., Ltd.

—— PRODUCT INTRODUCTION

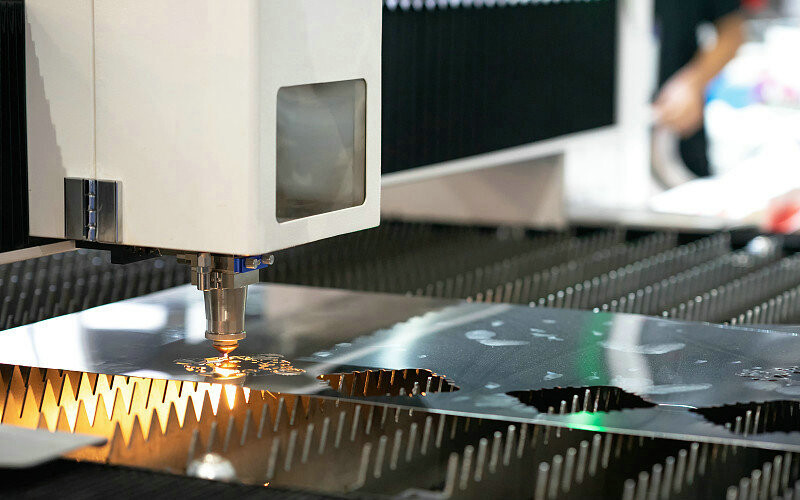

Pipe Laser Cutting Service Metal Stainless Steel Square Pipe Laser Cutting

Tube Laser Cutting

With laser cutting of tubes, the entire machining process from drilling, sawing, turning, milling and beveling can be done automatically, accurately and quickly! Not only does this mean savings and increased yields, it also gives you entirely new design possibilities.

Laser cutting of tubes is a thermal cutting process that enables high-quality cutting of all types of materials with wall thicknesses from 0.5 to 20 mm. The cutting results are impressive and can produce parts with an accuracy of 0.1 mm with minimal sharp corners and thermal shock. A focused laser beam melts narrow cuts in the substrate, and the melt is then blown out by cutting gas, leaving a clean cut with no slag inclusions. Thus, high-quality edges can be provided that do not require rework.

pipe laser cutting service OEM

Specification

Advantages of Laser Tube Cutting

Laser cutting tubes, the entire machining process from drilling, sawing, turning, milling and beveling can be done automatically, accurately and quickly! Not only does this mean savings and increased yields, it also gives you entirely new design possibilities. The assembly process can be optimized by adding positioning aids such as mortise and tenon, and assembly errors can be prevented by coding aids

Laser tube cutting technology intelligently combines the advantages of sheet metal and tube construction. As a result, many elements traditionally formed in sheet metal can be replaced or optimized.

Tube laser cutting machines are designed to cut hole profiles on round, square, oval, triangular and other special section tubes. Precise laser cutting of highly complex shapes within tubes is possible.

Tube laser cutting eliminates all traditional marking, sawing, drilling, deburring and forming operations performed in traditional tube processing. The traditional fixed costs of punches, jigs, tools and jigs are also eliminated.

Jiangsu Hailiang Dongfang Import and Export Co., Ltd.

—— ABOUT US

Jiangsu Hailiang Dongfang Import and Export Co., Ltd. is a professional metal parts manufacturer with years of experience in the industry, specializing in the production of various precision metal parts. Our business covers a wide range of areas, including CNC machining, metal stamping, mold parts manufacturing, forging, and casting, to meet the diverse needs of our customers. As a quality focused enterprise, we are committed to providing high-quality products at highly competitive prices. Every process is strictly controlled, and all products are screened layer by layer by advanced testing equipment and professional inspection teams to ensure their excellent performance, safety, and reliability. In addition, we attach great importance to after-sales service and have a professional and efficient customer service team to provide technical support and solutions to customers at any time, ensuring that customers have no worries during use. Jiangsu Hailiang Dongfang Import and Export Co., Ltd. has won the trust and praise of its customers with exquisite craftsmanship, strict quality management, and attentive service.

Jiangsu Hailiang Dongfang Import and Export Co., Ltd.

—— WHY CHOOSE US

High quality raw materials

Selecting high-quality steel raw materials ensures excellent product quality and performance from the source, leaving your project worry free.

Strict quality control

With advanced testing equipment and a professional team, all products undergo multi-stage rigorous testing to meet international standards, ensuring reliable and guaranteed quality.

Efficient logistics service

Cooperate with well-known logistics companies to establish a global logistics network, ensure fast and accurate delivery of goods, and ensure that your project progress is not affected.

after-sales team

An experienced after-sales team is always on standby to solve any problems you may encounter during use, providing technical support and attentive service.

Competitive Price

Factory direct sales, providing customers with more cost-effective products.

Jiangsu Hailiang Dongfang Import and Export Co., Ltd.

—— LEAVE A MESSAGE

Jiangsu Hailiang Dongfang Import and Export Co., Ltd.

—— RECOMMENDED PRODUCTS

ASK FOR A QUOTE