Packaging Details: Standard sea packing or as customer's request

Delivery Time: 3-15 working days according to the number of orders placed by customers

Payment Terms:L/C, D/A, D/P, T/T, Western Union, MoneyGram

Supply Ability: Supply 100,000 pieces per month

Model Number:OEM customization

If you have any questions, please feel free to contact us.

Jiangsu Hailiang Dongfang Import and Export Co., Ltd.

—— PRODUCT INTRODUCTION

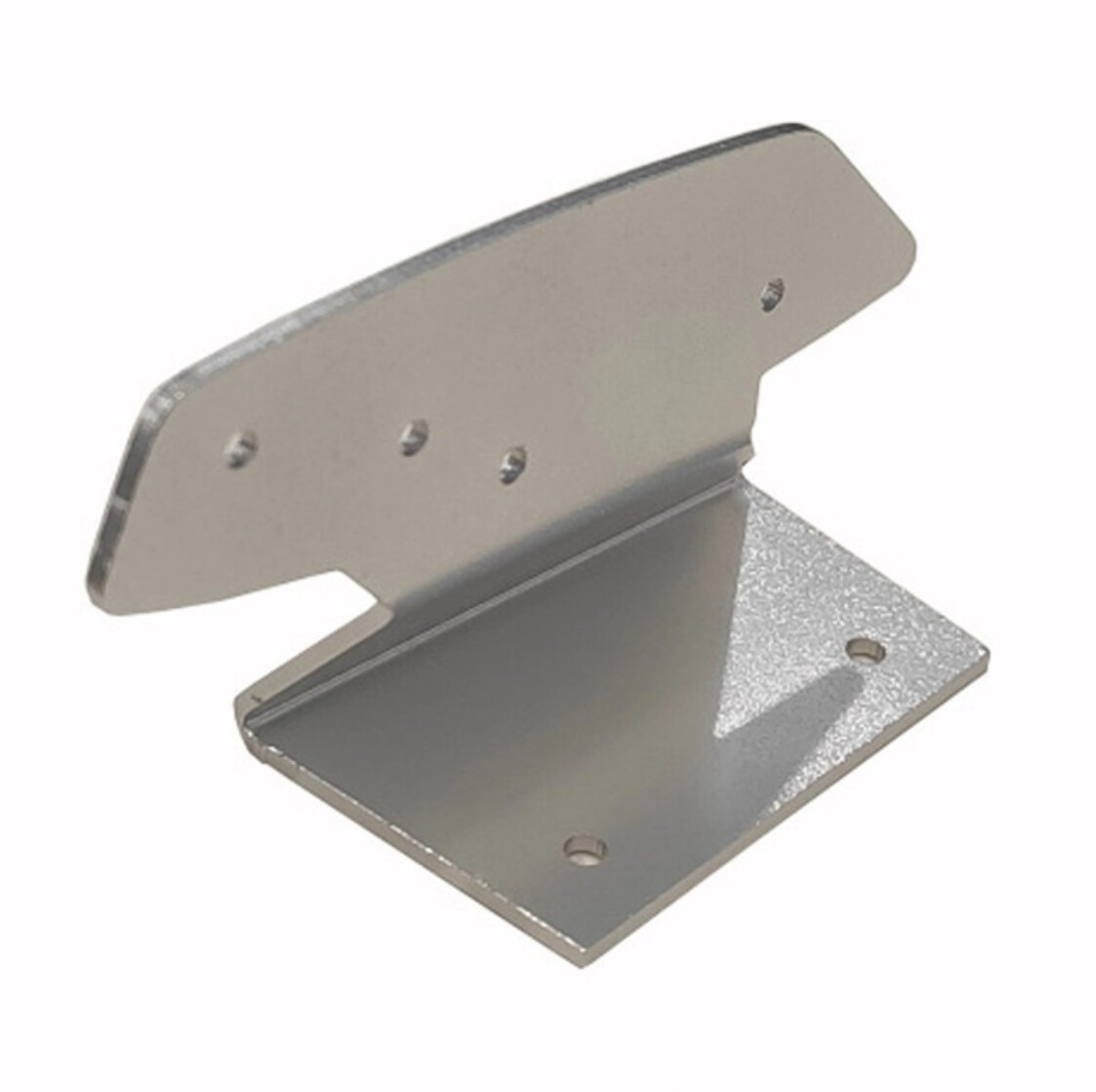

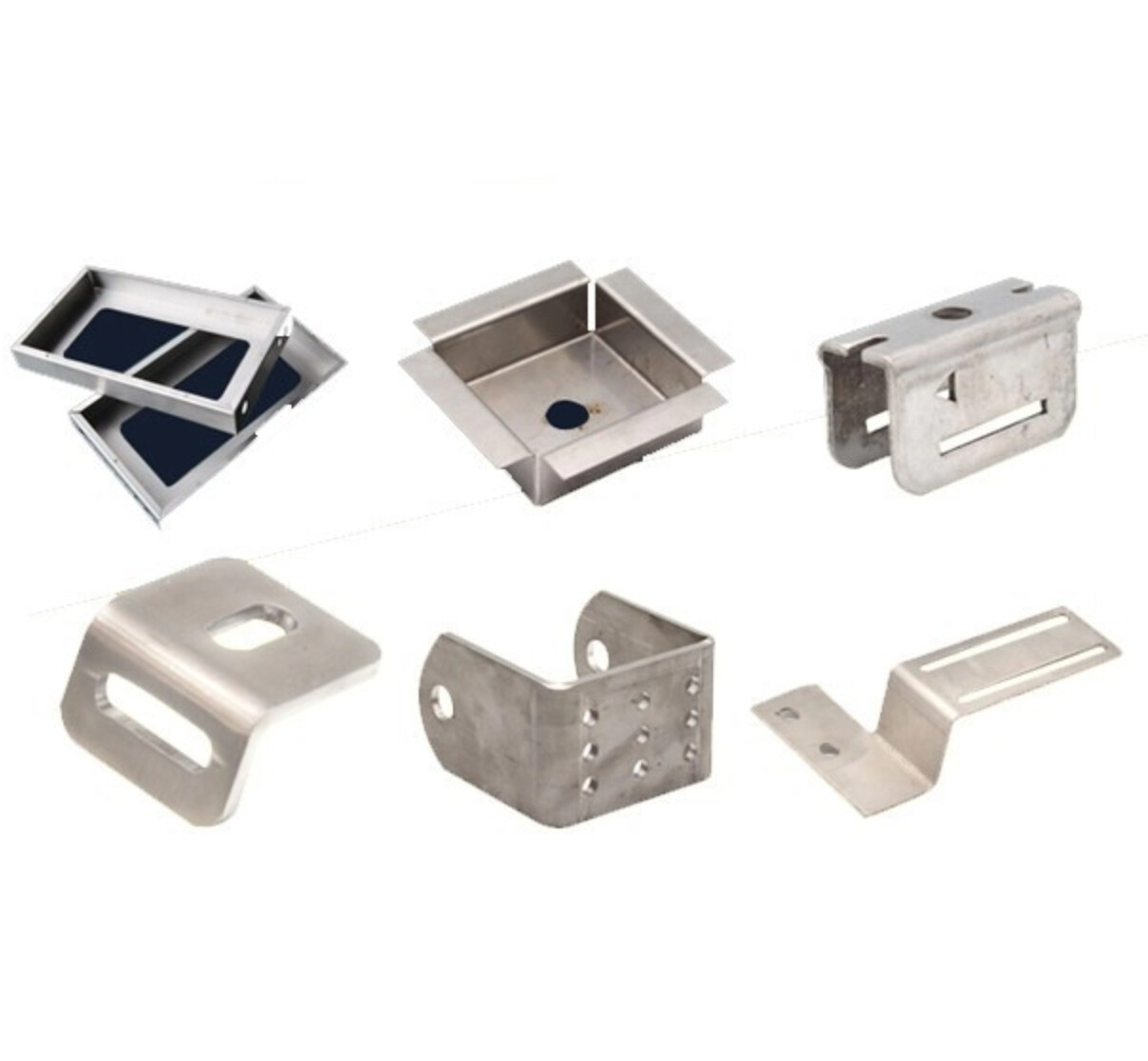

OEM Custom CNC Laser Cutting Sheet Metal Processing Stamping Bending Welding Services Steel Products

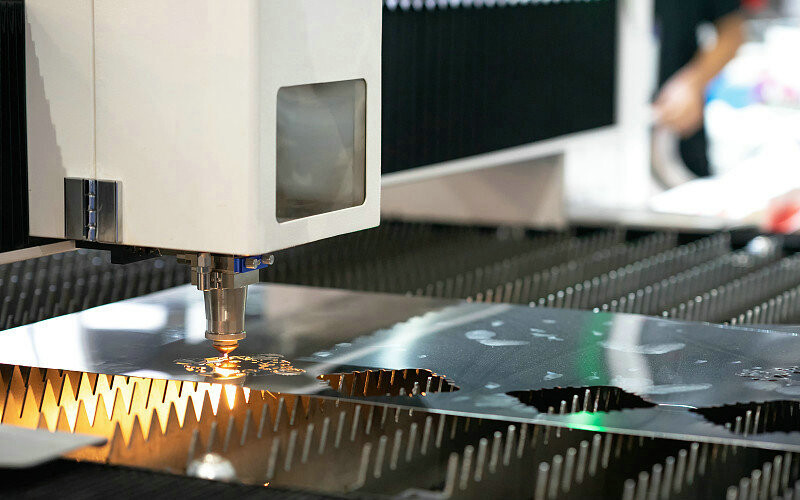

laser cutting

The custom coil-to-part precision laser cutting process and automated stacking greatly increases the speed and efficiency of the manufacturing process and reduces costs for our customers. We laser cut thin, high-precision metal parts from coils or sheets. Our laser cut custom metal parts have short lead times and tight tolerances

Our process produces scratch-free precision parts. Laser cutting thin metal parts as part of a manufacturing operation or the prototyping and development process is a fast and efficient method for producing parts

What is laser cutting?

Laser cutting is a process of cutting materials for industrial manufacturing applications by optically aiming a high-power laser. This type of fabrication is classified as a sheet metal cutting process because it is commonly used to cut this form of metal. However, laser cutting is also commonly used for high-quality welding and cutting of other materials such as composites, rubber, glass, wood and aluminum. There is also 3D laser cutting, which uses a CNC (Computer Numerical Control) machine to create deep cuts, while 2D cutting simply cuts pieces from a flat surface. This guide outlines all the basics of laser cutting services to help you make the best decision when requesting the service you need

Laser cutting involves the use of a focused, high-power coherent beam to cut through a material, usually a sheet. The material hit by the laser is vaporized and blown away by the gas to ensure a clean cut. Several types of lasers are available depending on the material that needs to be shaped, but they all rely on programming to perform specific cutting patterns to create one or more finished parts. While laser cutting is faster and more accurate than plasma cutting, you will find that waterjet cutting is more effective on thicker materials and materials with lower melting temperatures

product description

Jiangsu Hailiang Dongfang Import and Export Co., Ltd.

—— ABOUT US

Jiangsu Hailiang Dongfang Import and Export Co., Ltd. is a professional metal parts manufacturer with years of experience in the industry, specializing in the production of various precision metal parts. Our business covers a wide range of areas, including CNC machining, metal stamping, mold parts manufacturing, forging, and casting, to meet the diverse needs of our customers. As a quality focused enterprise, we are committed to providing high-quality products at highly competitive prices. Every process is strictly controlled, and all products are screened layer by layer by advanced testing equipment and professional inspection teams to ensure their excellent performance, safety, and reliability. In addition, we attach great importance to after-sales service and have a professional and efficient customer service team to provide technical support and solutions to customers at any time, ensuring that customers have no worries during use. Jiangsu Hailiang Dongfang Import and Export Co., Ltd. has won the trust and praise of its customers with exquisite craftsmanship, strict quality management, and attentive service.

Jiangsu Hailiang Dongfang Import and Export Co., Ltd.

—— WHY CHOOSE US

High quality raw materials

Selecting high-quality steel raw materials ensures excellent product quality and performance from the source, leaving your project worry free.

Strict quality control

With advanced testing equipment and a professional team, all products undergo multi-stage rigorous testing to meet international standards, ensuring reliable and guaranteed quality.

Efficient logistics service

Cooperate with well-known logistics companies to establish a global logistics network, ensure fast and accurate delivery of goods, and ensure that your project progress is not affected.

after-sales team

An experienced after-sales team is always on standby to solve any problems you may encounter during use, providing technical support and attentive service.

Competitive Price

Factory direct sales, providing customers with more cost-effective products.

Jiangsu Hailiang Dongfang Import and Export Co., Ltd.

—— LEAVE A MESSAGE

Jiangsu Hailiang Dongfang Import and Export Co., Ltd.

—— RECOMMENDED PRODUCTS

ASK FOR A QUOTE