Packaging Details: Standard sea packing or as customer's request

Delivery Time: 3-15 working days according to the number of orders placed by customers

Payment Terms:L/C, D/A, D/P, T/T, Western Union, MoneyGram

Supply Ability: Supply 100,000 pieces per month

Model Number:OEM customization

If you have any questions, please feel free to contact us.

Jiangsu Hailiang Dongfang Import and Export Co., Ltd.

—— PRODUCT INTRODUCTION

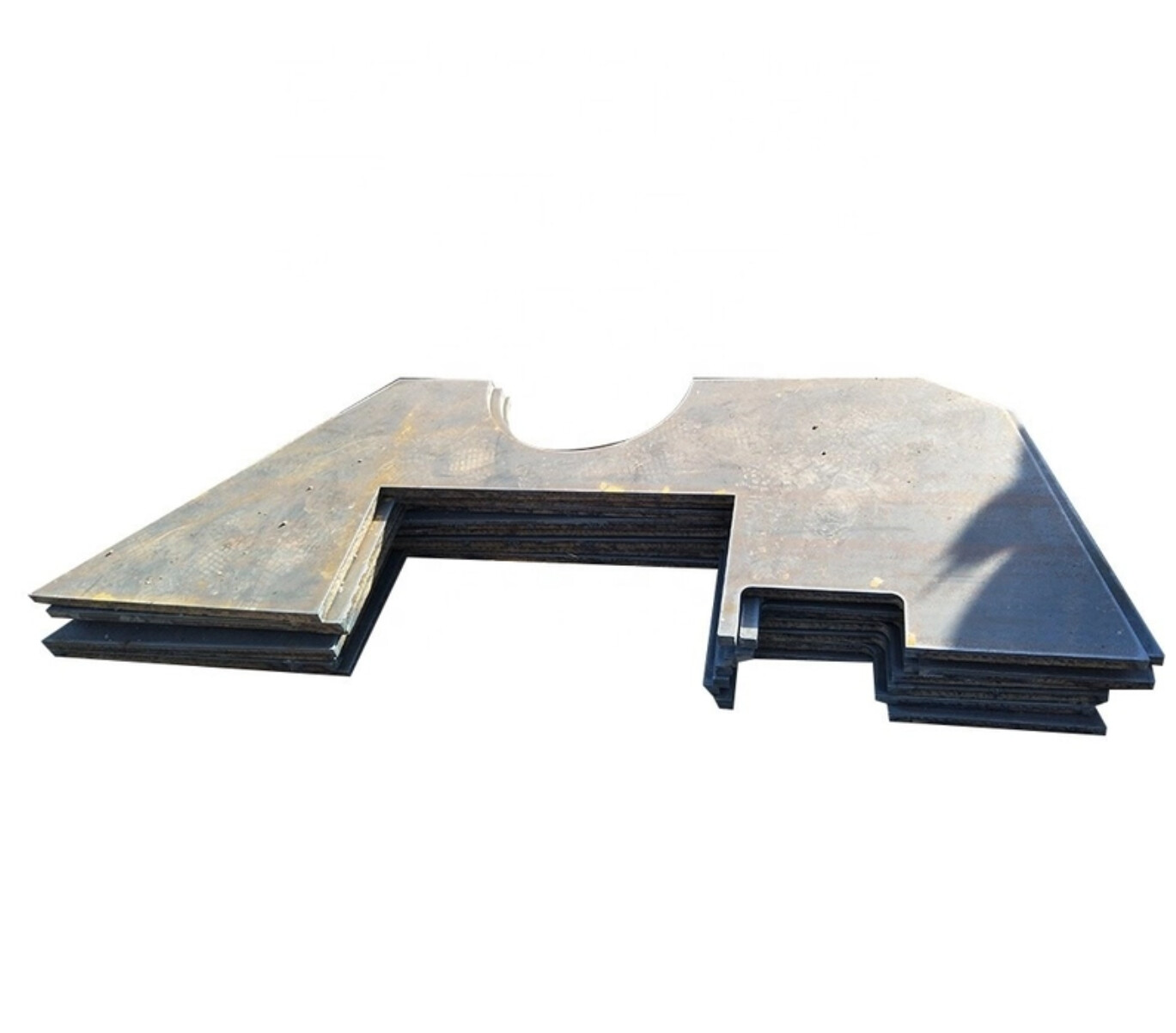

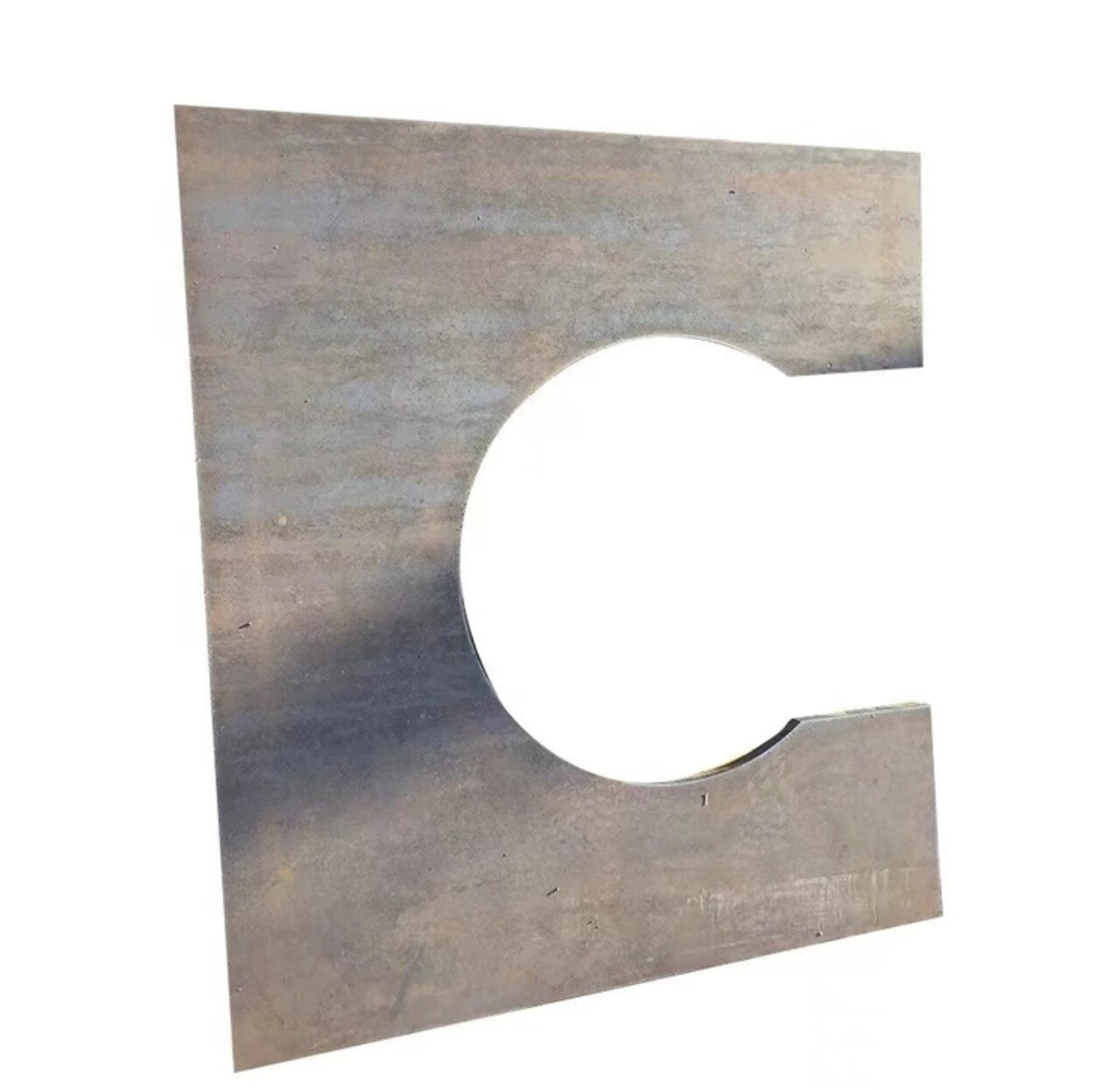

CNC Flame Cutting High Strength Steel Plate S355J2 for Heavy Metal Extra Thick Plate Cutting Service

What is flame cutting?

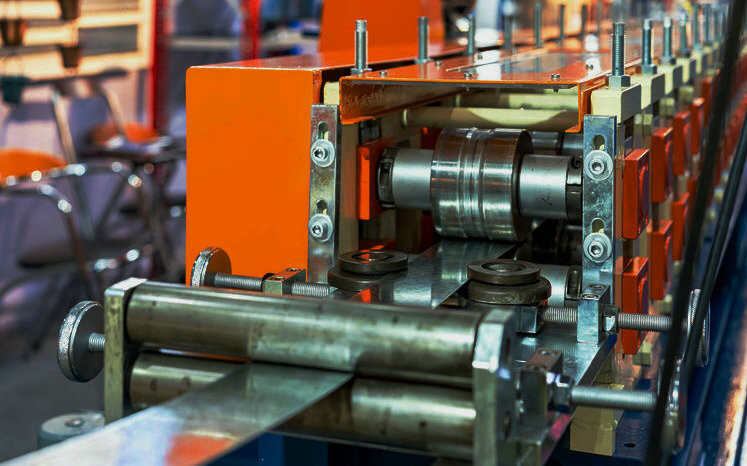

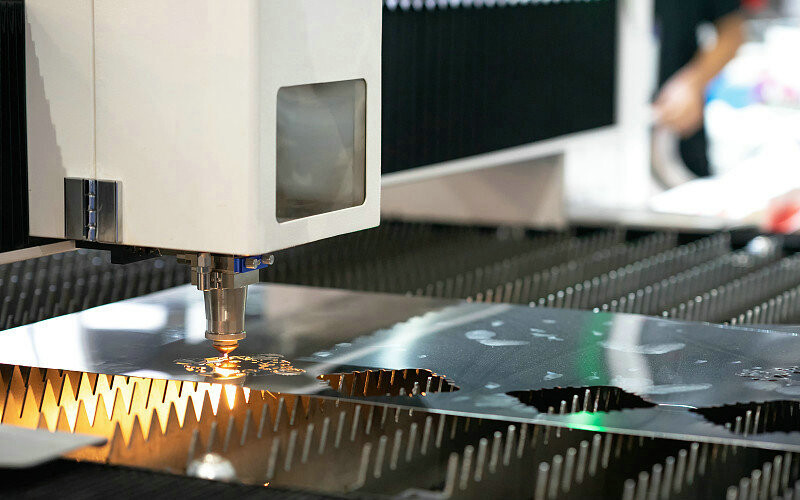

CNC flame cutting (oxyfuel) uses a combination of liquid oxygen and cutting gas. Torch moves over the plate to burn parts of specified shape and size to produce crisp, clean cuts

Flame cutting or "burning" of carbon steel sheets is an effective and efficient method of cutting carbon and alloy steel sheets to size and shape

Combustion starts by heating a spot on the edge or surface of the plate with an oxy-fuel flame, then injects a high-pressure stream of pure oxygen when that spot becomes red hot. Both preheated flame and cutting oxygen are delivered through specially designed nozzles or tips

In the presence of a cutting oxygen stream, the hot steel actually burns, combining with the oxygen to form iron oxide

It is this combustion that cuts the sheet as the cutting oxygen flow advances along the cutting path. Combustion releases high temperatures above 2800 degrees Fahrenheit, which melts steel near the cutting path

Custom Metal Fabrication

The metal fabrication process is the foundation of modern manufacturing. With precision techniques such as oxy-fuel flame cutting, manufacturers can easily achieve the tight tolerances and smooth surfaces required by OEMs and industry customers

Metal fabrication refers to the high volume manufacturing techniques used to process raw metal into functional parts. Custom metal fabrication services allow customers in all industries to benefit from these processes

While each project requires a different set of methods, the broader manufacturing process consists of three stages

design:CAD models and specifications of customer-developed components. Metal fabrication specialists help modify these designs, if necessary, and create a fabrication plan

manufacture:Manufacturers use a range of fabrication methods, including cutting, grinding, and processing, to complete design specifications

Finishing and Assembling:Once manufactured, the part may undergo various finishing processes designed to improve its function in a specific environment. For example, heat treatment can strengthen steel components, making them more resistant to strain. Finally, manufacturers assemble products that involve multiple components

product description

Jiangsu Hailiang Dongfang Import and Export Co., Ltd.

—— ABOUT US

Jiangsu Hailiang Dongfang Import and Export Co., Ltd. is a professional metal parts manufacturer with years of experience in the industry, specializing in the production of various precision metal parts. Our business covers a wide range of areas, including CNC machining, metal stamping, mold parts manufacturing, forging, and casting, to meet the diverse needs of our customers. As a quality focused enterprise, we are committed to providing high-quality products at highly competitive prices. Every process is strictly controlled, and all products are screened layer by layer by advanced testing equipment and professional inspection teams to ensure their excellent performance, safety, and reliability. In addition, we attach great importance to after-sales service and have a professional and efficient customer service team to provide technical support and solutions to customers at any time, ensuring that customers have no worries during use. Jiangsu Hailiang Dongfang Import and Export Co., Ltd. has won the trust and praise of its customers with exquisite craftsmanship, strict quality management, and attentive service.

Jiangsu Hailiang Dongfang Import and Export Co., Ltd.

—— WHY CHOOSE US

High quality raw materials

Selecting high-quality steel raw materials ensures excellent product quality and performance from the source, leaving your project worry free.

Strict quality control

With advanced testing equipment and a professional team, all products undergo multi-stage rigorous testing to meet international standards, ensuring reliable and guaranteed quality.

Efficient logistics service

Cooperate with well-known logistics companies to establish a global logistics network, ensure fast and accurate delivery of goods, and ensure that your project progress is not affected.

after-sales team

An experienced after-sales team is always on standby to solve any problems you may encounter during use, providing technical support and attentive service.

Competitive Price

Factory direct sales, providing customers with more cost-effective products.

Jiangsu Hailiang Dongfang Import and Export Co., Ltd.

—— LEAVE A MESSAGE

Jiangsu Hailiang Dongfang Import and Export Co., Ltd.

—— RECOMMENDED PRODUCTS

ASK FOR A QUOTE